Sheet Metal Services

QCA Central has state of the art sheet metal machines and equipment with the latest technology which provide only the best equipment, staff, and services for our customers who require sheet metal fabrication.

Read More

The Adaptable Fabrication Division

The Adaptable Fabrication Division

The Adaptable Fabrication Division

Established in 1996 and located in Fort Smith, Arkansas, QCA Central [formerly American Precision Fabricators] has been a reliable source for quality American-made products. Our capabilities were expanded in 2020, becoming sister-division to Quality Circuit Assembly- a well renowned electronics manufacturer based in San Jose, California. This pairing has allowed QCA Central to provide turnkey solutions to industrial problems nation-wide and around the globe.

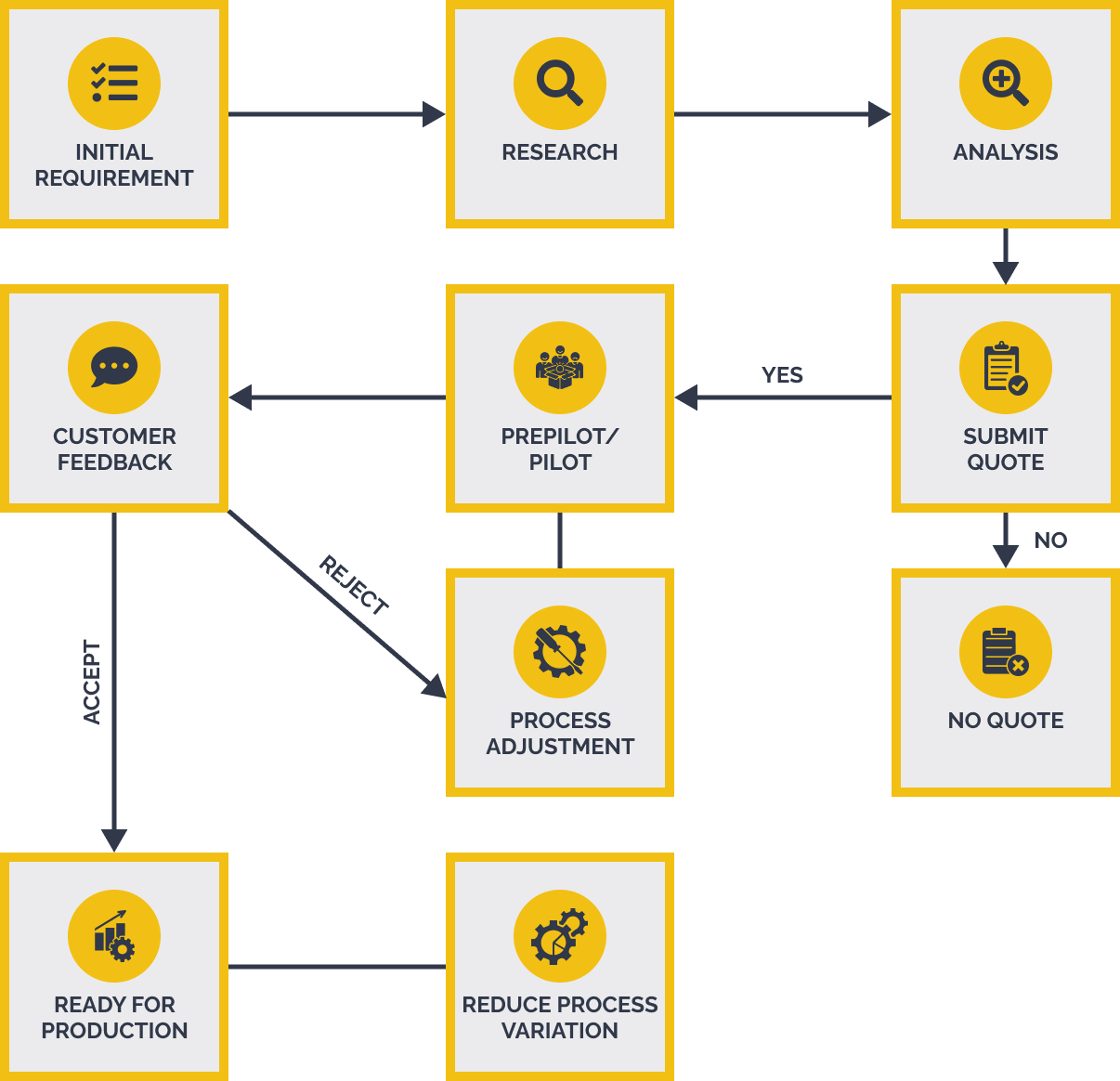

We provide a quote for single part in 48 hours or less; Quotes for larger packets (7 parts or greater) are typically completed within 7-10 days. Our Lead time turnaround is the standard lead time of 7-14 days.

QCA Central has state of the art sheet metal machines and equipment with the latest technology which provide only the best equipment, staff, and services for our customers who require sheet metal fabrication.

Read MoreAt QCA Central, we pride ourselves on the wide range of assembly services for metal fabricated parts or EMS (electro-mechanical) parts, such as wiring and harnesses.

Read More